Startseite » Innovation

Potential, future and forecasts

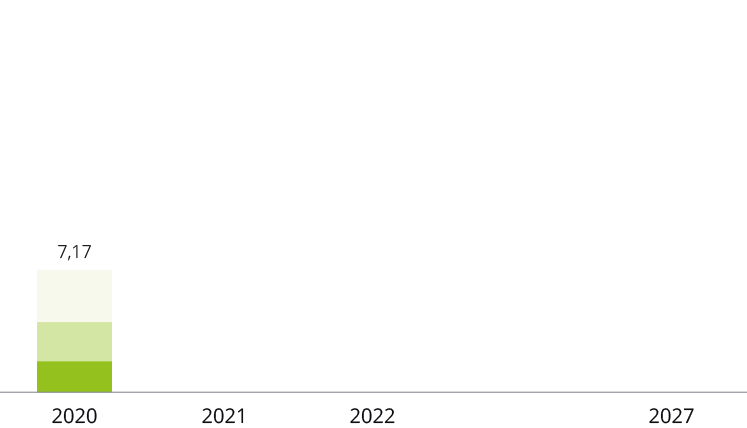

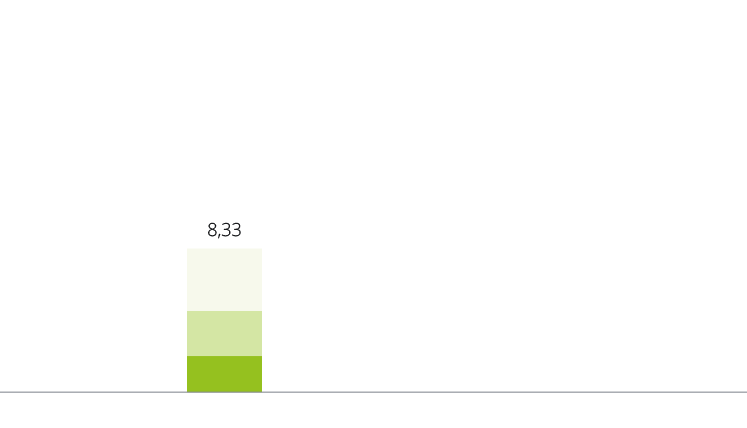

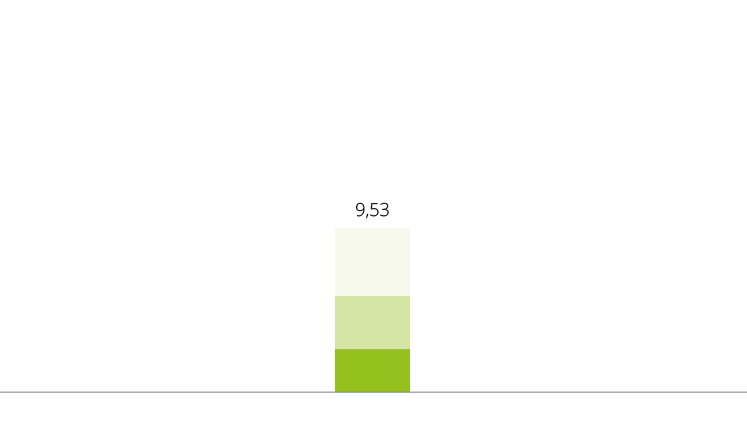

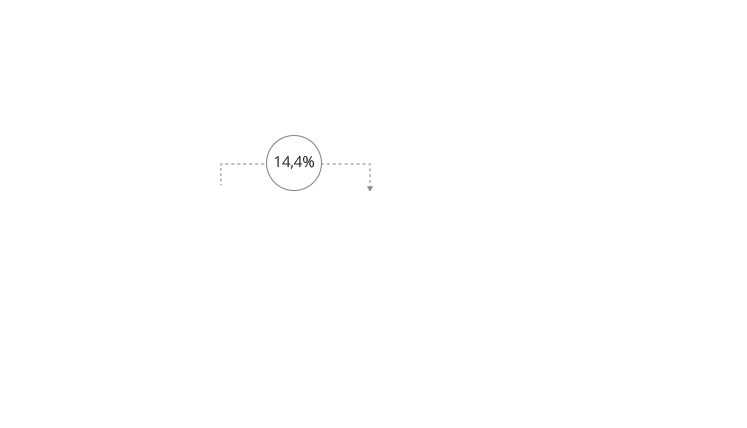

The industrial additive manufacturing of metals and polymers is undergoing rapid development. The 2023 AMPOWER Report predicts that the global market will grow at an average CAGR of 17.7%.

These predictions are partly due to the fact that with the further development of metal-based 3D printing, even the most demanding metal applications can now be efficiently additively manufactured. Important innovations in the field of support-structure-free laser melting, for example, are now looking increasingly likely and will significantly reduce costs when implemented. As a result, new applications in fields such as medical technology or mechanical engineering will become economically successful – a positive development sure to be reflected in their market growth.

Source: additive-manufacturing-report.com

© Copyright 2023, AMPOWER GmbH & Co. KG

The additive manufacturing market is driven by several factors, including:

“We are ready for these dynamic future developments and will be happy to assist you with advice and support in the implementation of your 3D printing tasks!”

Welcome to the FKM Experience Lab! At FKM, everything revolves around the practice-oriented implementation of innovative applications of additive manufacturing. We use state-of-the-art technologies and materials to achieve ‘first-time-right’ solutions for our customers. Our team of experienced experts turns your ideas into tailor-made components.

PA 613 is a thermoplastic polyamide powder that is being used in a completely new way in SLS technology at FKM. The material is an outstanding development that combines the advantages of the well-established plastics PA 6 and PA 12 and offers the best of both worlds. Its surface resolution and detail are excellent – making it ideal for beautiful surfaces in series production. The material is characterised by its greater strength and rigidity. PA 613 is also resistant to moisture and chemicals and retains its shape and dimensions even at higher temperatures.

Learn more

This high-performance polymer based on an unfilled PEKK has produced impressive test results. It has a higher elongation at break and impact strength while maintaining higher tensile strength than the carbon-fibre-filled material HT-23. PEKK-100 is particularly impressive at high operating temperatures in the range of 80–180°C. It has similar properties to injection-moulded 35% glass-fibre-filled polyamide 6 and is therefore ideal as a replacement for small series applications, especially in the automotive industry.

Learn more

Diversity.

6 Plastics. 6 metals.

What advantages must the material have for your application? Tensile strength, fracture resistance, temperature resistance, bending flexibility or lightness?

Whatever components you need to produce, FKM has the right material to meet every requirement. Put your trust in our experience – together we will find the perfect material.

With a comprehensive material selection of pure or filled plastics, large-volume and flexible 3D printing capacities and validated parameter sets, we reliably achieve optimum product properties for your parts.

Our comprehensive portfolio of highly developed metal materials has proven itself in daily practice. The modern metal powders ensure the desired product properties and make the reproductions reliably repeatable.

Industrial 3D printing has evolved tremendously in recent years, enabling innovation in the following industries, among others:

3D printing of prototypes (rapid prototyping), production of spare parts on demand and rapid tooling (3D production of tools)

3D printing of complex parts, lightweight components and rocket motors that are difficult to produce using traditional manufacturing processes

3D printing of individualised prostheses, orthoses, implants, dentures and surgical instruments

3D printing of complex components, prototypes of electronic components and housings and rapid tooling (tools and fixtures produced using 3D printing)

3D printing of sports equipment such as shin guards, helmets, shoes and racquets, as well as made-to-measure eyeglass frames with custom designs

Sie haben Fragen?

Nehmen Sie zu uns Kontakt auf.

Do you have any questions?

Please get in touch with us.